EPS molds are used to create custom-shaped expanded polystyrene

foam products.

Mold Materials:

Aluminum and steel are common mold materials for EPS. Aluminum is lightweight and cost-effective, while steel offers

greater durability and precision.

The mold material must be able to withstand the heat and pressure

of the EPS expansion process.

Mold Cavity Design:

The mold cavity shape directly determines the final product

geometry. Careful 3D modeling and simulations are needed to optimize the

cavity design.

Draft angles, ejection mechanisms, and parting line placement are

critical for part removal and dimensional accuracy.

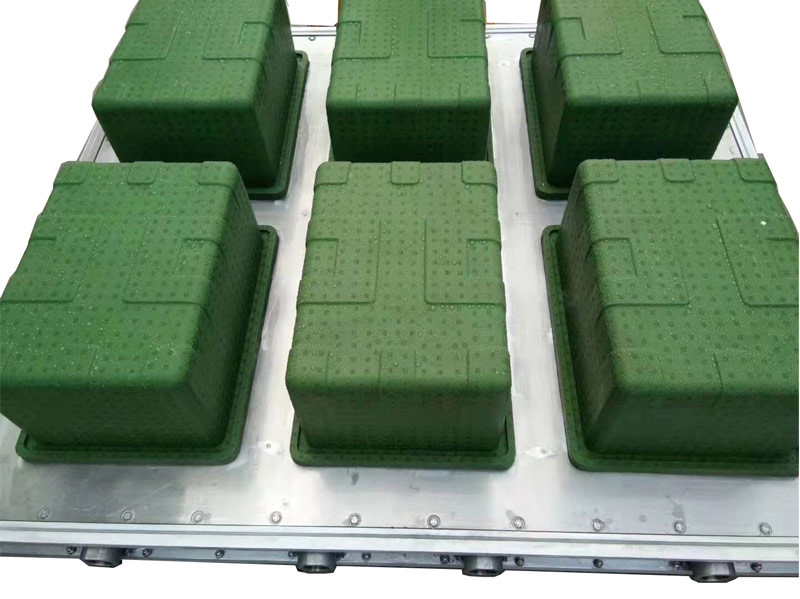

Multi-cavity molds allow for higher production volumes in a single

cycle.

Bead Fusion:

The EPS beads must properly fuse together within the mold to create

a cohesive, structural part.

Bead size, density, and fusion properties affect the mold design

and expansion process parameters.

Improper bead fusion can lead to weak points or voids in the final

EPS product.

Manufacturability:

Cycle time, demolding, post-processing, and packaging needs must be

considered for efficient, high-volume production.

Mold cooling, heating, and automation features impact the overall

manufacturing process.

Simulation and Prototyping:

CAE (computer-aided engineering) tools are used to model the mold

filling, bead expansion, and part ejection.

Physical prototyping and testing help validate the mold design

before full-scale production.

Designing an effective EPS mold requires expertise in materials,

manufacturing processes, and part design.