NINGBO PINSHENG MACHINERY CO.,LTD

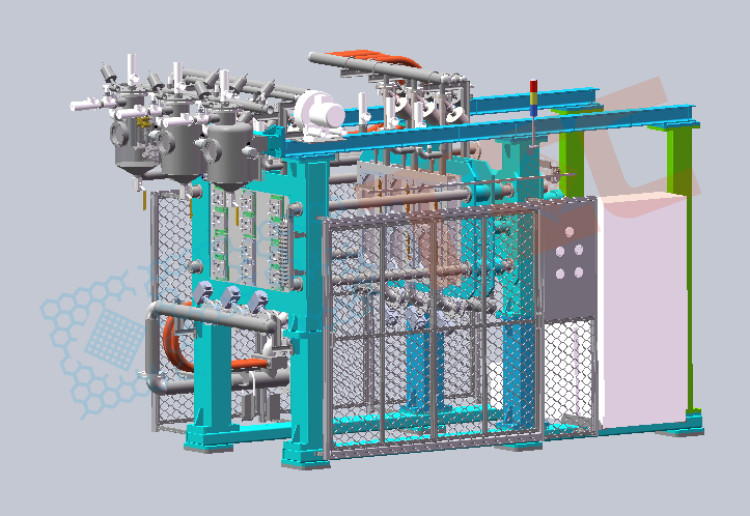

NINGBO PINSHENG MACHINERY CO.,LTD.specializes in manufacturing

EPS,EPP,ETPU machine and EPS Mould for nearly 10 years with

integrating independent R&D,production, sales and service.Our

Factory is located in Hangzhou, the fast developing district in

China, and close to important ports such as Shanghai and Ningbo,the

geographical position is superior, transportation and shipping are

very convenient.

Pinsheng Company focus on the product's quality and technical

innovation,with professional working team and strong processing

capacity.Our service is efficientand professional, and the

pre-sale, sale, after-sales service personnel are

skilled,experienced, and timely response.